Engineering Plastics

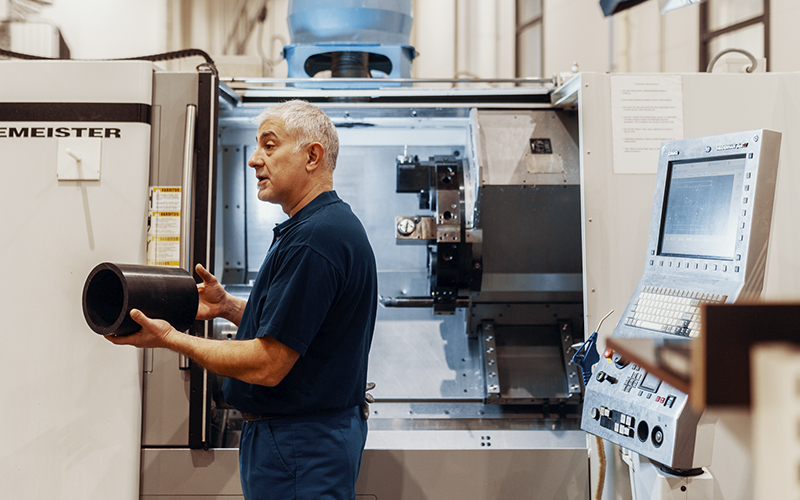

Etra Engineering Plastics offers machined plastic products parts based on the customer’s drawings through machining methods with chip removal. These include machine-building components such as gliding and wear parts, bearings, sleeves, rollers, wheels, runners, raising pieces etc. In engineering plastics production, we use modern CNC machinery to manufacture plastic components from plastic sheets, rods and tubes for applications in e.g. machine building, process industry, paper and forest industry, chemical industry, shipbuilding, and pharmaceutical and food industries. We assist you in designing plastic products for your needs. Material certificates are available for our products upon request.

Products and Services

- Comprehensive range of engineering plastics, also for high temperature environments

- High-quality machined plastic parts based on your drawings

- Customer-specific material and product storing

- Packaging for the finished product based on your needs

- Quick and flexible fullfilment schedule

The range of engineering plastics

Materials and Suppliers

Etra Engineering Plastic manufactures and assist in designing products that suit the customer’s needs from high-quality plastic material. Distribution and maintenance services are available in Etra Megacenters. Our main supplier for engineering plastics is Mitsubishi Chemical Advanced Materials (formerly Quadrant).

Engineering Plastics

Polyamides (PA), Polyacetals (POM), Polyethylene terephthalate (PETP), UHMW PE 1000, PE 500, PE 300, Polytetrafluoroethylene (PTFE), Polyvinylidene fluoride (PVDF), Polypropylene (PP), Phenolics (PF), Polyurethane (PUR), Polybenzimidazole (PBI), Polyamide-imide (PAI), Polyether ether ketone (PEEK), Polyphenylene sulphide PPS, Polyphenylsulphone (PPSU1000), Polyetherimide (PEI), Polysulphone (PSU)

Design and Calculating Service

When selecting materials, material properties, such as surface pressures, tensile strength, temperature resistance, coefficient of heat expansion, water absorption, chemical strain, and friction factors, must be considered.

Etra Engineering Plastics calculating service determines suitable characteristics with computer-assisted applications, including bearing clearances, surface pressures tolerances, and loadbearing capacity.

We also provide training for your customers in engineering plastics.

Production Technology

Automated and modern machinery combined with graphical production design ensure the highest quality end product and excellent delivery reliability. We invest continually in innovation that enhance cost-efficacy and create value for our customers.

- Automated sawing

- Automed five-axle machining, thread milling and marking

- CNC machining

- Plastic welding

- Plastic 3D printing

- Part assembly

Quality and Documentation

High quality is the core objective in all our processes. All of our products have a 100% traceability from used materials to the finished product. Quality-driven mindset combined with expertise, cutting edge production technology and up-to-date production facilities lead to best possible results.

- Measurement documentation on all products.

- Surface quality measuring

Quality Certificates