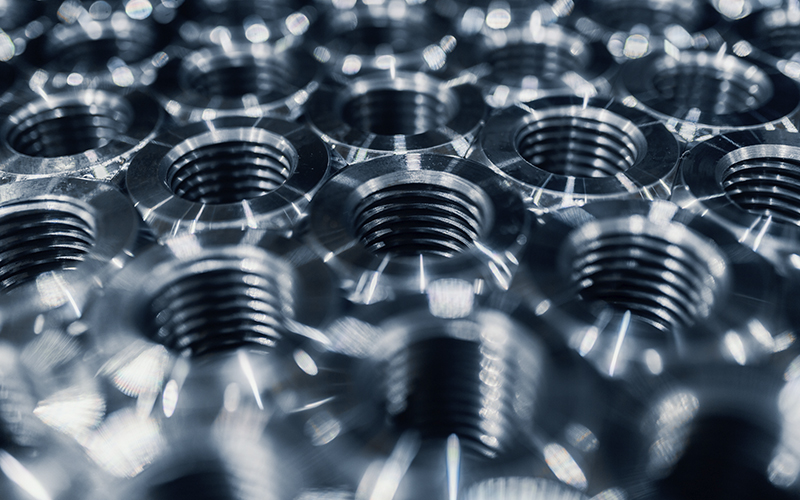

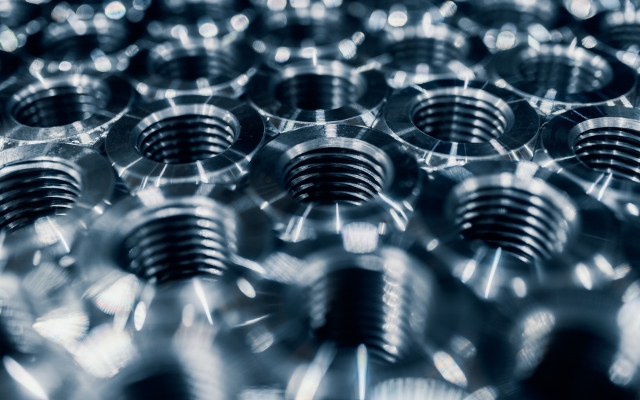

Fasteners Production

We manufacture custom-designed, technically demanding special fasteners such as bolts, U-bolts, screws, studs, washers, and nuts. For hot forging, CNC machining, and thread rolling, we use modern machinery and automation that ensure efficient production and excellent quality. Our quality assurance also relies on high-grade raw materials, measurement reports, ultrasonic testing, magnetic particle inspection, hardness testing, tensile and impact tests, as well as other material testing methods. When required, material certificates and classification society certifications are available for our products.

Our key customer segments include the process industry, paper and forest industry, chemical industry, shipbuilding, energy production, and mining industry. Our location near Helsinki-Vantaa Airport and the Port of Vuosaari ensures fast delivery routes worldwide.

Products and services

- We manufacture products according to our customers’ drawings, such as bolts, U-bolts, studs, nuts, and washers.

- We stock customer-specific raw materials and finished products, and we also package the finished products according to our customers’ requirements.

- Quality assurance is carried out in compliance with the customer’s quality guidelines (FMEA, AQL, SPC, ISIR, Control Plan).

Materials

A heat-specific certificate is always available for the raw materials used in our production. PED 2.1, 2.2, 3.1, and 3.2. We accept only the best and most reliable suppliers as our raw material providers to ensure the high quality of the final product.

- Structural steels

- Quenched and tempered steels

- Stainless and acid-resistant steels

- Cold-, heat-, and hot-resistant steels

- Pressure vessel steels

Quality and certificates

High quality is the core objective of all our processes. The products we manufacture always have 100% traceability from the raw material used to the final product. A quality-oriented mindset, combined with expertise, the latest production technology, and modern production facilities, ensures the best possible outcome.

- Measurement reports for all products. We can also use the customer’s own measurement report if required

- Surface quality measurement

- NDT: magnetic particle inspection (MT), penetrant testing (PT), ultrasonic testing (UT)

- DT: hardness testing (Brinell, Rockwell, Vickers), tensile, bending, and impact testing, as well as metallographic examinations

- Classification societies: ABS, BV, CCS, CR, DNV GL, IRS, KRS, LRS, NK, RINA, and PRS

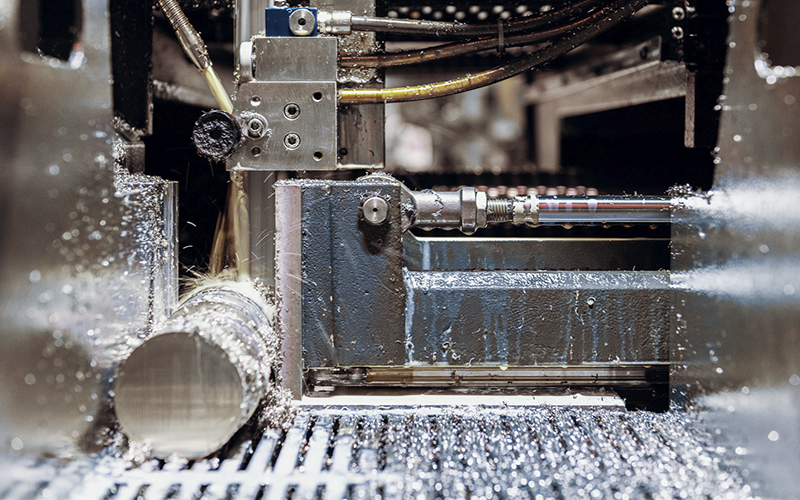

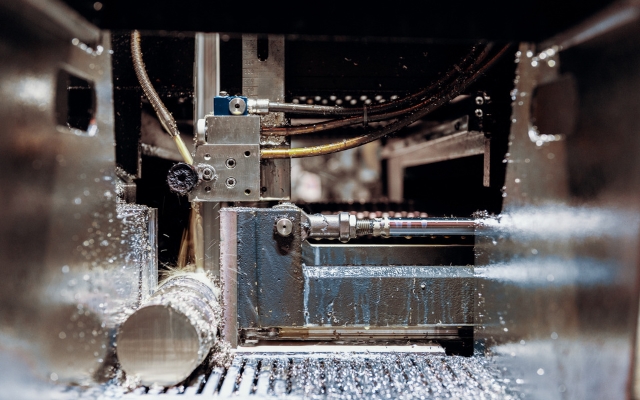

Manufacturing Technology

Automation, modern machinery, and decades of experience ensure the high quality of our final products. We develop our operations according to the principles of continuous improvement.

- Automatic sawing

- Robotic CNC machining and thread rolling

- Product marking

- Hot forging and bending

- Heat and surface treatments

- Sub-assembly